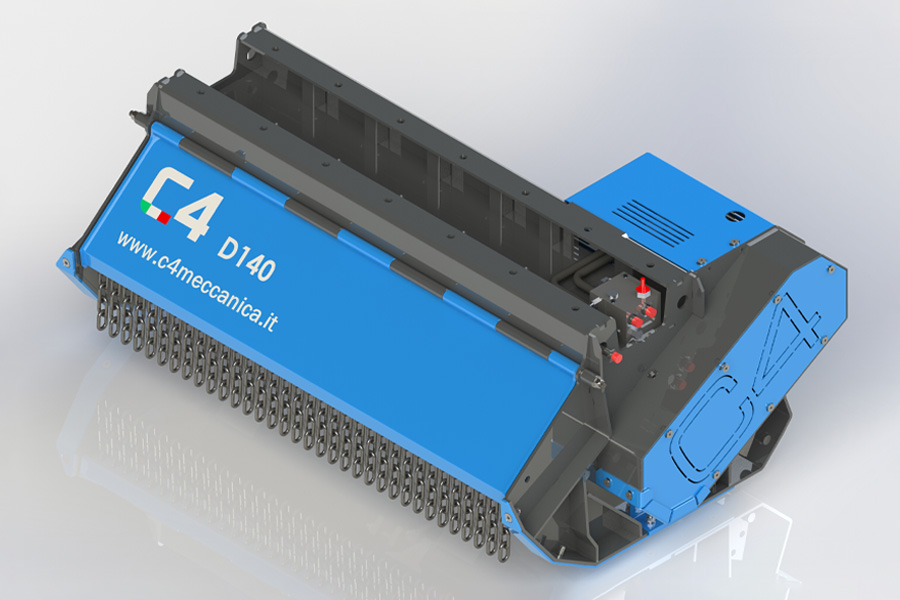

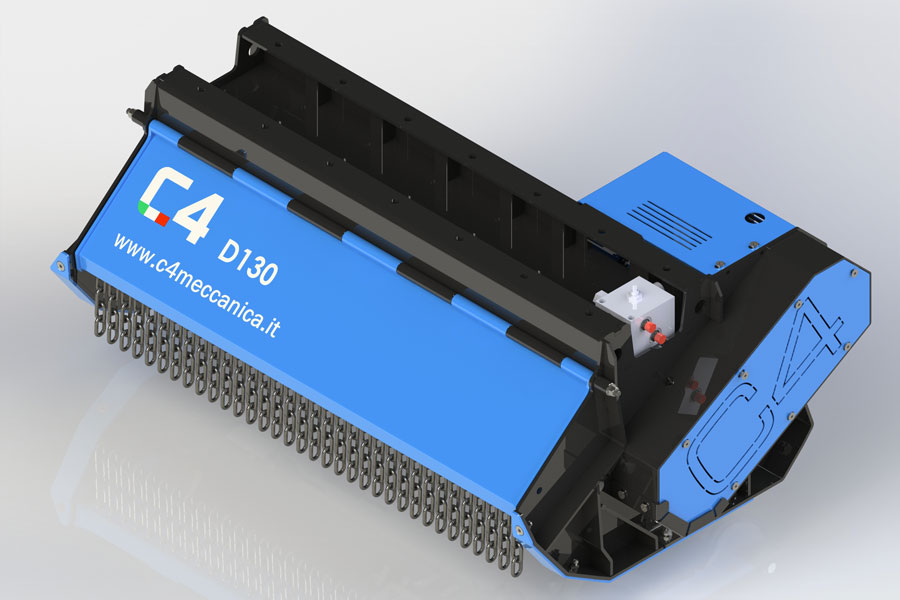

Series D – Hydraulic Mulchers for excavators from 6 to 15 Ton

Description

Available in 3 versions: D120 – D140 – D170

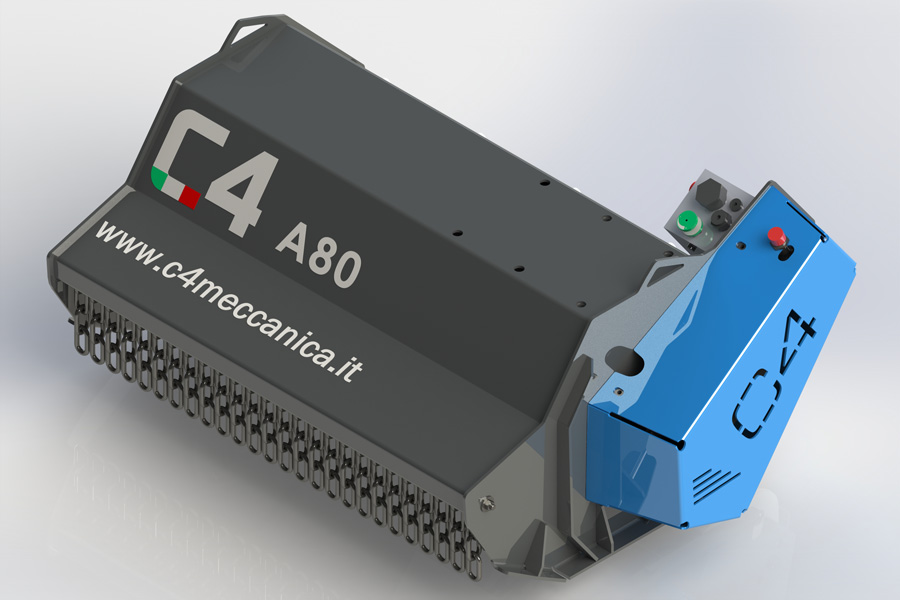

- Predisposition of holes for the positioning of the attachment along the entire length of the mulcher.

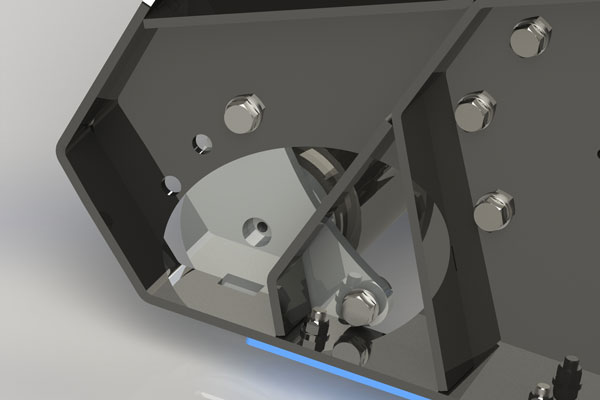

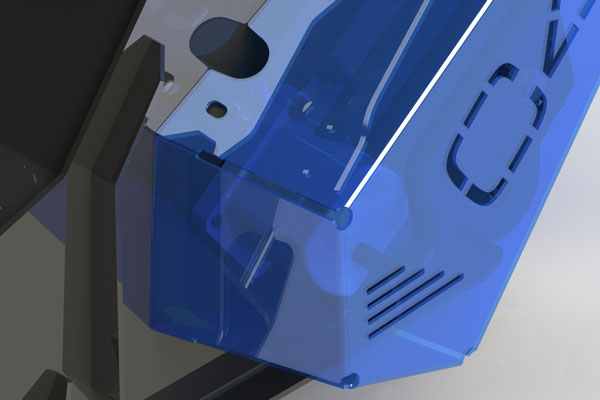

- Fluidbox for complete and safe engine management, with maximum shockproof valve, anti-cavitation system and flow regulation to set the rotor speed correctly.

- Replaceable wear-resistant skids.

- Double bottom case to increase strength and optimize the cutting volume.

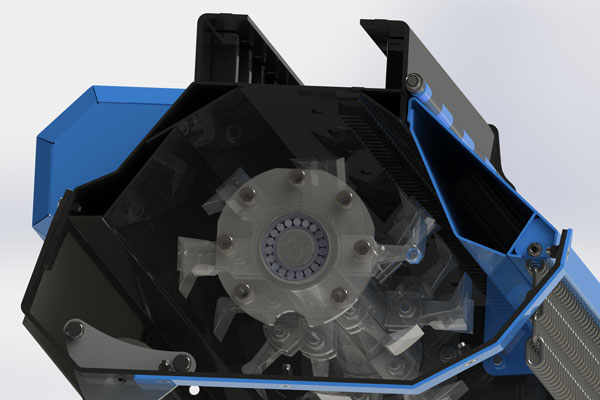

- Triple knife • Hammer

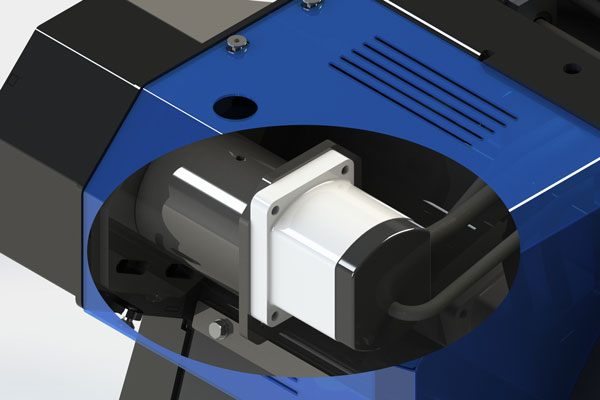

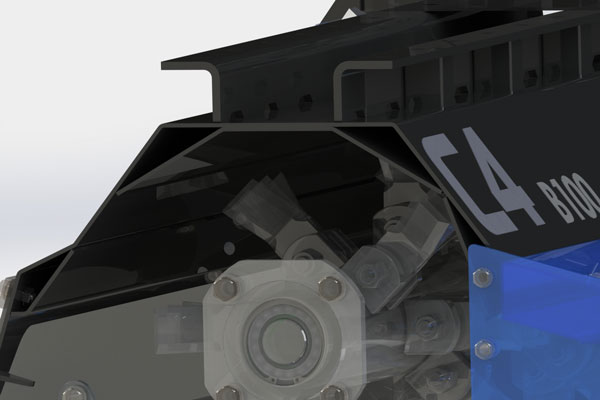

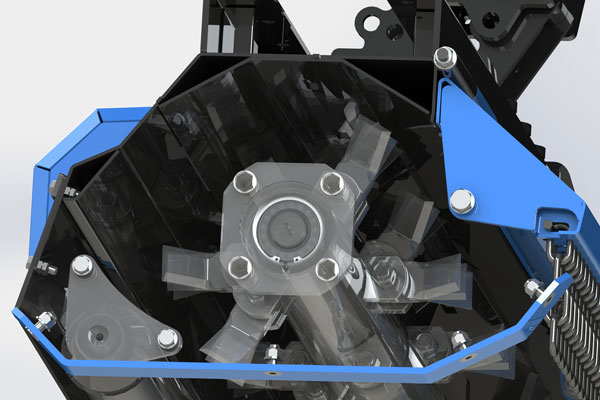

- Motor mounted on support with bearings to avoid premature wear of the engine, with casing for impact protection. Belt transmission, essential for applications where the transmitted powers begin increasing, thanks to the elastic joint that has the function to preserve both the motor and the rotor from unexpected stresses.

- The machine is standard in a two-pipe configuration, the fluidbox will manage the flow of oil coming from engine drainage. In the event that the back pressure at the discharge is greater than 8 bar, it’s possible to provide the third drainage tube for direct tank discharge.

- Rotor can be equipped with three-blade knives for higher shredding capacity and lower demand of power. Rotor can be equipped with hammers to tackle branches and shrubs up to 75 mm in diameter.

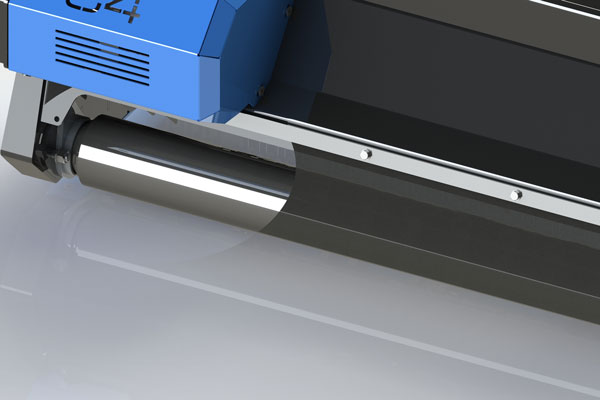

- Rear support roller adjustable in 3 positions for cutting height adjustment. Rear protection strip in wear- resistant rubber.

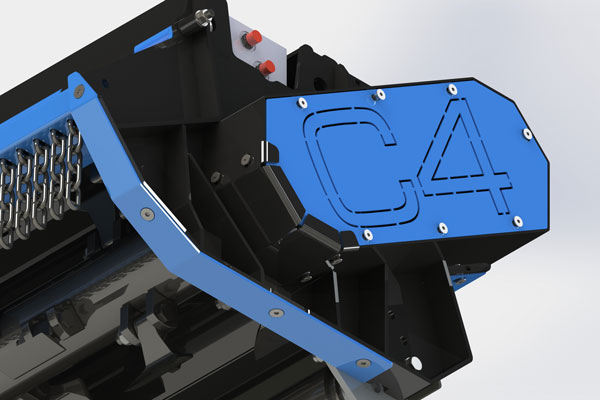

- Front protection with chains, adjustable in two positions for easy maintenance.

Optional

- Standard with 2 mt hydraulic hoses. Optionally available: set of tubes with customized lengths.

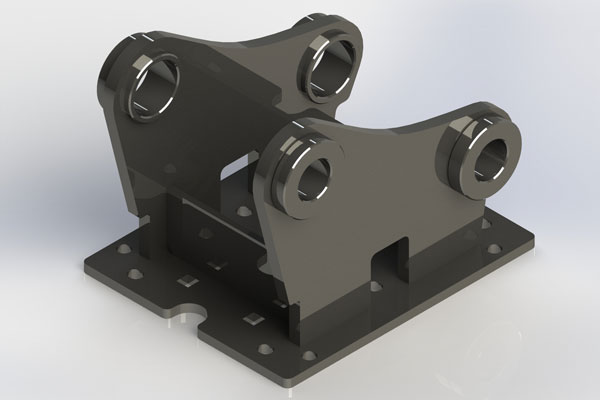

- Available as an optional: standard attachment and pins with customized measurements, flat plate for attachment as standard.

- Available as optional: specific self-levelling support.